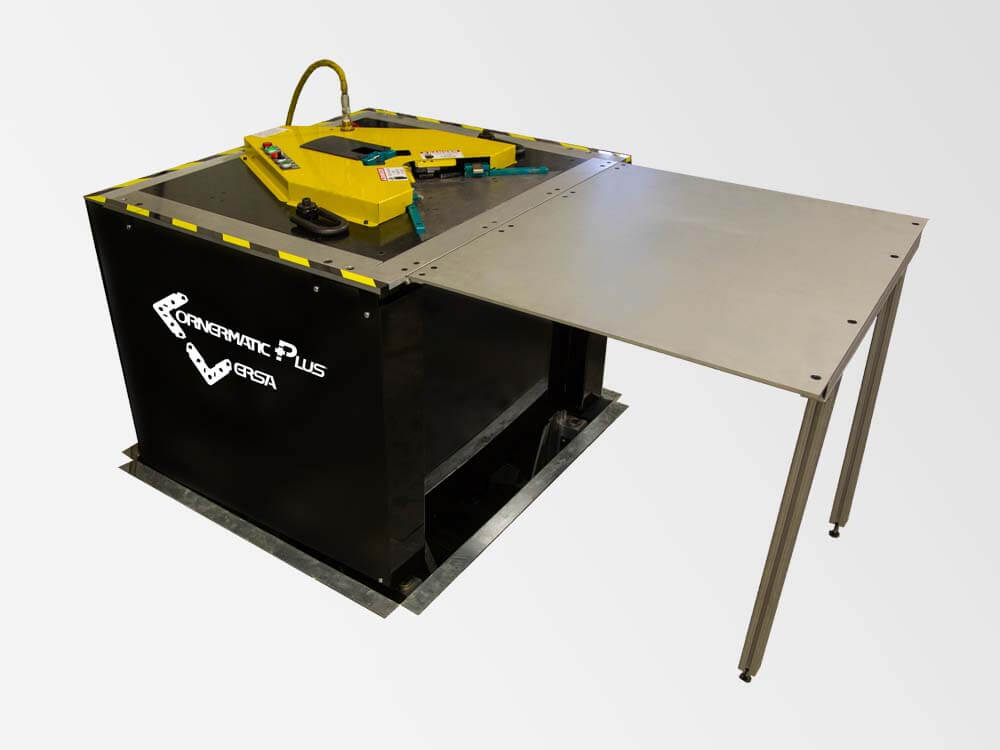

The Cornermatic machine is a type of metalworking machine used for cutting corners if you need facade cassettes. The variety of existing machine types can be explained by the way they work. Only fixed corners can be made by the simplest model, which distinguishes it from modified corner-cutting presses in which the cutting angle can be adjusted.

Cornermatic machines and presses are used for cutting corners in sheet steel workpieces that require further bending of the perpendicular sides. For example: case parts, panels, doors, pallets. Angle-cutting machines and presses are characterized by high productivity, which leads to an increase in the rate of production.

Angle-cutting presses can be equipped with different types of drives. For example, manual, electromechanical and hydraulic. Which option to choose? It all depends on the volume of production. For a small production it is enough and a manual angular cutting machine. A large enterprise will require the use of electromechanical and hydraulic drives.

Online stores represent high-capacity angle-cutting presses. This equipment is widely used in metal working shops for a wide range of profiles. Machines are multifunctional and easy to operate, that makes it possible to buy corner-cutting presses even for small private workshops.

The machines are controlled by a user-friendly controller that displays all the data required by the operator in real time. Corner cutters and presses thus provide full control of the working process and allow for the best controlled cutting of corners in metal constructions. You may also be interested in Pittsburgh best lock former.

Advantages of angle cutting machines

Professional equipment for metalworking, which you can inexpensively buy on the network, has high production and performance characteristics. All presented angle-cutting machines are:

- Durable and wear-resistant. This allows you to reduce the cost of production of blanks and the cost of depreciation of the equipment.

- Powerful and ready for everyday use. Available professional cornering machines are ready for daily smooth operation, provided timely preventive maintenance in the time period specified by the manufacturer.

- You can buy it really cheap. If you are looking for an inexpensive, yet high quality and reliable angle cutting machine, you can always find such options.

Hurry up to optimize your work on processing metal structures using effective and convenient equipment from the world leader.

Angle-cutting machine with delivery

Hurry up to choose and buy the best a cornermatic machine with delivery to your production. This will save you time in starting up a new production area, as well as money in scaling up production, because the cost of delivery can be affordable. The optimal machine for your workshop is already waiting for you in our extensive catalog.

Corner-cutting machines are used for cutting corners of different shapes in workpieces and are then bent on a segment bending machine. More often angular cutting machines are used for production of box-shaped wares from sheet metal, facade cassettes, cases of electric devices. Also with the help of punching machines can perform punching of various holes in the metal.

Angle-cutting machines are divided into manual, hydraulic and pneumatic according to the type of drive. Manual angle-cutting machines are used for cutting corners and piercing holes in metal with fixed thickness, they have compact size and high performance. You can choose all the necessary equipment and buy it at favorable prices if you use the site of a proven seller.